World-class Six-Sigma Processes

Jan 30, 2022

Various levels of Sigma

Over the last 4-5 decades, a lot has been discussed about Six Sigma which is a highly effective approach which creates improvement in business processes of an enterprise. It uses both statistical and analytical methods to reduce variation in the end products.

Let’s understand the percentage of defects each sigma level can accommodate in any process through the following table.

Just to elaborate on the above table, Let’s say, if we are producing 1 million number of products or transactions (in service industry) and if your process is so robust that it doesn’t produce more than 3 defects out of these, your process is said to be working at a 6-Sigma level.

On an average, most of the processes in any industry (Manufacturing or Service) are working at 3 –sigma level. Which means, they are producing 66,807 defects* (on an average). This also means that we have to improve the process by 20,000 times to bring it to the 6-Sigma level.

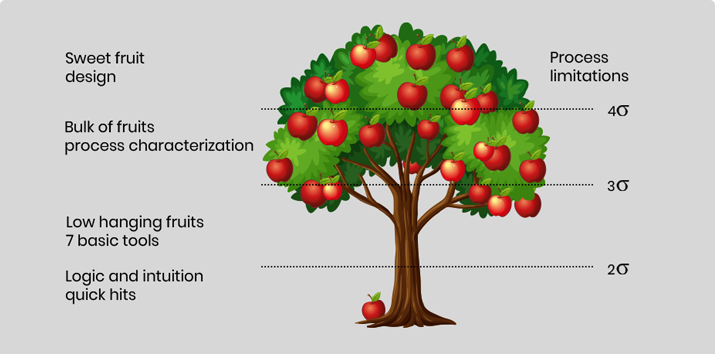

Harvesting the fruit of six sigma

As depicted in the above picture, while it takes only ‘Logic and intuition quick hits’ to bring your process to a 2-sigma level, it takes significant efforts to elevate it to 6-sigma level which includes both the process as well as the data door.

Following are some of the examples of the processes which follows the 6-sigma standards.

Flights Operations

On an average there are 100,000 flights which operates each day globally (36.5 million in a year). Unfortunately, out of which, on an average, 87 flights crash each YEAR. Therefore, Operation of flights is a six sigma process.

Cash withdrawal from the ATM

How many times do you count cash after withdrawing from an ATM? And even if you count, have you ever got more money than opted for?

Never, Right? ATM transactions also qualifies for six sigma process.

Mumbai Dabbawalas

This is a classic example of a Six Sigma process which Mumbai Dabbawalas implemented unknowingly.

The Mumbai Dabbawallas deliver food every day from the home to the workplace and they do it with minimal technology, processes, or structure. They became world renowned as a six sigma organization, and were studied by Harvard University.

In 1998, Forbes global magazine conducted a quality assurance study on the Dabbawalas operations and gave them the rating 99.999999.

Dabbawalas made only one error in 6 million transactions and stood high along with MNCs like Motorola, GE etc.

Six Sigma examples are great ways of helping one understand the characteristics and benefits of techniques used during its implementation. There are several Six Sigma project modules which use these examples to help the learner understand the manner the system operates.

*Defect is something which does not fit into customer specification boundaries